The presence of metals, phosphorus and soaps are not wanted in refined edible vegetable oils because of these act as prooxidants. Content of metals should be limited to below 0,2 ppm for each metal present and content of soaps should be zero in a good quality and stable refined oil.

Most metals, like copper and nickel with exception of phosphorus and some iron, come into the oil through dissolution during processing or storage in tanks. Washing and bleaching operations in the process are not very effective for the elimination of metals and soaps. On the other hand, excessive use of wash water may overload the treatment plant. One of the economical solutions for this purpose is to use an absorbent with high affinity against soaps and metals. Those are generally known as “selective silicas”.

Pure-Flo® bleaching clays are effective in absorbing soaps because they are produced from selected special raw materials. However, poor washing or high soap content may result in excessive use of clay in oil bleaching process. (Every 50 ppm soap above 40-50 ppm would require use of 0,1 % more clay then that would be necessary for decolorisation in general.)

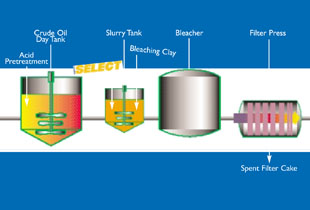

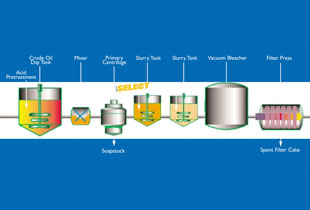

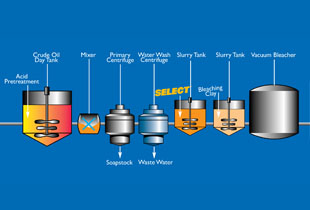

Oil-Dri’s "Select 350 ®" branded product is designed to remove metals, phosphorus compounds, and soaps in edible oils. It would be sufficient to use this material 2-4 times the amount of soap in the oil preferably before bleaching process. Its use would be economical at those levels although its price is much higher than that of any bleaching earth.